A highly efficient design that enables one operator to:

-

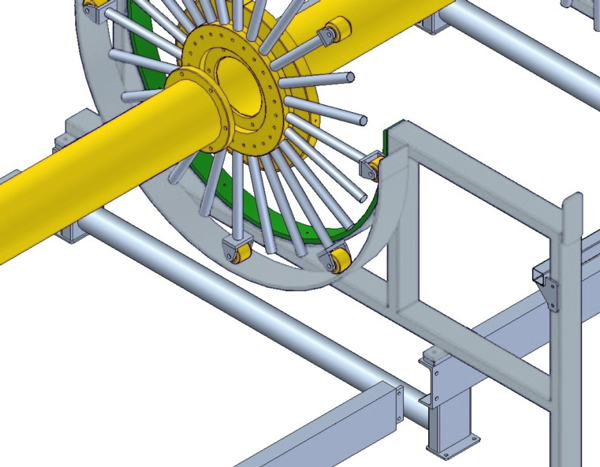

Change discs quickly without additional labour or the use of a crane

-

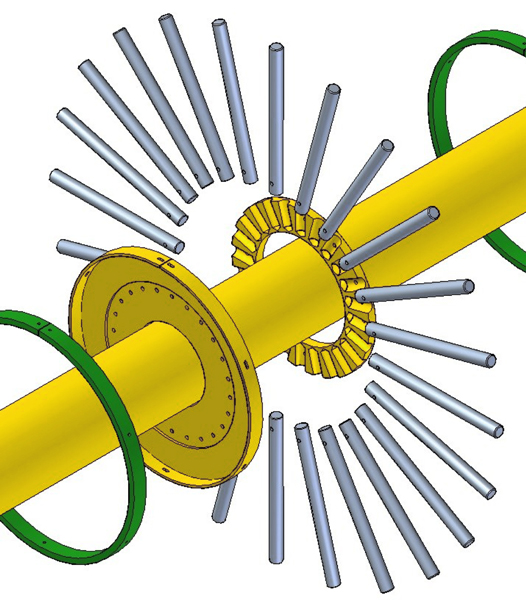

Position and reposition bushes accurately within the ring discs

-

Adjust all welding parameters directly from the control panel

-

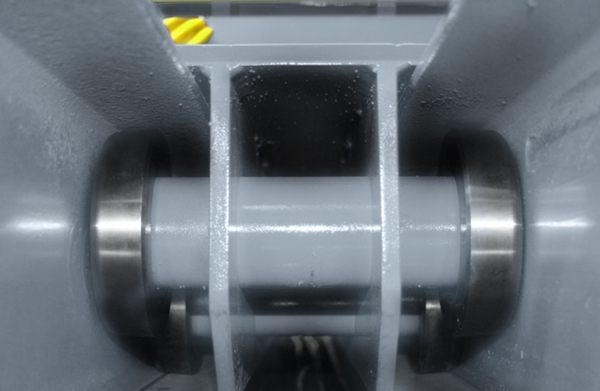

Use the pneumatic clamp bush for bars up to Ø32 mm with central release

-

Benefit from “Smart Assistance” technology for automatic calculation of pile cage diameters and precise bush positioning

-

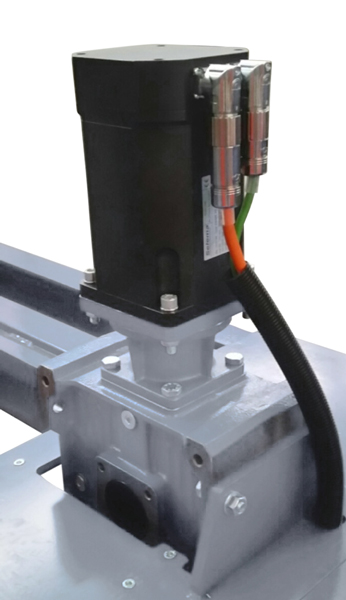

Ensure accuracy through software-controlled laser sensors — no mechanical adjustments needed

-

Rely on “Smart Load” functionality to help the operator correctly position each bar

-

Easily insert lifting bands or rings within the pile cage before fabrication begins

-

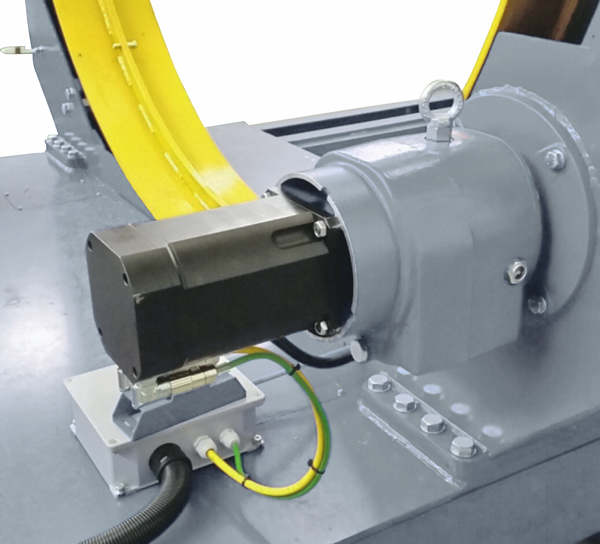

Choose the upgraded straightening unit option with more powerful motors for producing spirals up to Ø20 mm